Vokera Easi Heat Plus Manual: A Comprehensive Guide

Navigating the complexities of your heating system is now simpler! This detailed manual provides essential guidance, covering installation, operation, and troubleshooting for optimal performance.

Unlock the full potential of your Vokera Easi Heat Plus boiler with clear instructions and expert advice, ensuring efficient and reliable home comfort for years to come.

Welcome to the world of efficient home heating with the Vokera Easi Heat Plus! This boiler represents a significant advancement in domestic heating technology, designed to deliver reliable warmth and hot water while prioritizing ease of use and energy efficiency. The Easi Heat Plus is a condensing boiler, meaning it recovers heat that would otherwise be lost, resulting in lower fuel consumption and reduced carbon emissions.

This manual serves as your comprehensive guide to understanding, installing, operating, and maintaining your Vokera Easi Heat Plus boiler. Whether you are a homeowner, a heating engineer, or simply seeking to learn more about your heating system, this resource will provide you with the information you need. We’ll cover everything from initial setup and commissioning to troubleshooting common issues and performing regular maintenance.

Understanding the core principles of your boiler is key to maximizing its performance and longevity. This introduction will lay the groundwork for a deeper dive into the system’s components, features, and operational procedures, empowering you to enjoy consistent and cost-effective heating throughout your home.

Understanding the System Components

The Vokera Easi Heat Plus boiler comprises several key components working in harmony to deliver efficient heating and hot water. At its heart lies the heat exchanger, responsible for transferring heat from the combustion gases to the water circulating through the system. A modulating fan adjusts the gas supply for optimal combustion, maximizing efficiency based on heating demand.

The pump circulates the heated water throughout your radiators or underfloor heating system, while the diverter valve directs flow either to the heating circuit or the hot water tap. A crucial element is the PCB (Printed Circuit Board), the boiler’s ‘brain’, controlling all functions and safety features. The gas valve regulates gas flow, and the pressure relief valve ensures safe operation by preventing excessive pressure build-up.

Familiarizing yourself with these components is vital for effective maintenance and troubleshooting. Understanding their function allows for quicker identification of potential issues and informed communication with a qualified heating engineer. Regular inspection of these parts contributes to the longevity and reliable performance of your Vokera Easi Heat Plus boiler.

Boiler Features and Specifications

The Vokera Easi Heat Plus boasts a range of features designed for efficiency and user convenience. It’s a condensing boiler, meaning it recovers latent heat from exhaust gases, achieving higher efficiency ratings – typically exceeding 90%. The compact design allows for flexible installation in various locations, including kitchen cupboards.

Key specifications include a range of power outputs (typically from 24kW to 30kW), suitable for different home sizes and heating demands. It operates on natural gas and features a fully modulating output, adapting to precisely match heat requirements. The boiler incorporates frost protection, preventing damage during cold weather, and a scale inhibitor to reduce limescale build-up.

Furthermore, the Easi Heat Plus offers a user-friendly interface with a clear digital display for easy operation and diagnostics. It’s compatible with a variety of controls, including remote control and smart thermostats, enhancing comfort and energy management. The boiler’s robust construction ensures durability and long-term reliability.

Control Panel Overview

The Vokera Easi Heat Plus control panel is intuitively designed for straightforward operation. A prominent digital display clearly shows the current boiler status, including temperature settings, error codes, and operational mode. Navigation is typically achieved through a combination of buttons – often labelled ‘Mode’, ‘Temperature Up/Down’, and ‘Reset’.

The ‘Mode’ button allows you to select between heating and hot water operation, or switch the boiler to ‘Off’ or ‘Reset’ mode. Temperature adjustment buttons control both the central heating and domestic hot water temperatures. The display will indicate the set temperatures. Error codes, should they appear, provide valuable diagnostic information – refer to the troubleshooting section of this manual for details.

A reset function is crucial for resolving minor issues, but should only be used after carefully reviewing the error code and understanding its potential cause. The panel also features indicator lights for key functions, such as flame detection and water pressure. Familiarizing yourself with these elements ensures efficient boiler control.

Initial Setup and Commissioning

Proper initial setup is vital for the Vokera Easi Heat Plus’s longevity and efficiency. Before powering on, verify all gas and water connections are secure and comply with local regulations. A qualified Gas Safe registered engineer must perform the commissioning process. This involves checking gas pressure, flue operation, and ensuring correct appliance settings.

The engineer will configure the boiler to your specific system requirements, including setting the maximum heating and hot water temperatures. They’ll also perform a system flush to remove any debris that could damage the boiler. Following this, the system will be filled and bled to eliminate airlocks, ensuring optimal heat distribution.

Crucially, the engineer will explain the control panel operation and safety features. They should provide documentation confirming the installation meets all relevant standards. Do not attempt to operate the boiler until commissioning is complete and you’ve received clear instructions. Retain all commissioning documents for future reference and servicing.

Filling the System with Water

Correctly filling the heating system is crucial before initial operation and after any significant leaks. Locate the filling loop, typically near the boiler, featuring two isolation valves and a flexible hose. Ensure both valves are closed before proceeding. Connect a garden hose to the filling loop’s inlet.

Slowly open the mains water supply and then the first valve on the filling loop. Observe the boiler’s pressure gauge; the ideal pressure is generally between 1 and 1.5 bar (check your specific model’s requirements). As the pressure rises, periodically open and close the bleed valves on radiators to release trapped air.

Once the desired pressure is reached, close the filling loop valve first, then the mains water supply. Disconnect the hose. Regularly check the system pressure and top up as needed. Never over-pressurize the system, as this can damage components. If you are unsure, consult a qualified heating engineer.

Operating the Vokera Easi Heat Plus

The Vokera Easi Heat Plus is designed for user-friendly operation. After ensuring the system is filled and pressurized, the boiler will automatically ignite when heating or hot water is demanded by a thermostat or tap. The control panel displays key information, including temperature settings and any error codes.

For central heating, adjust the room thermostat to your desired temperature. The boiler will modulate its output to maintain that temperature. To activate hot water, open a hot water tap; the boiler will fire up to provide instant hot water; The system prioritizes heating based on demand.

Familiarize yourself with the control panel’s functions for adjusting settings and monitoring performance. Regularly check the pressure gauge and address any low-pressure warnings promptly. Remember to consult the troubleshooting section for assistance with common issues. Safe and efficient operation relies on understanding these basic principles.

Setting the Temperature

Adjusting the temperature on your Vokera Easi Heat Plus is straightforward. Utilize the control panel’s intuitive interface to modify both central heating and hot water temperatures independently. For central heating, the thermostat controls the room temperature, communicating with the boiler to maintain the setpoint.

To increase or decrease the central heating temperature, use the corresponding buttons on the thermostat or the boiler’s control panel, depending on your system configuration. Hot water temperature is similarly adjusted via the control panel, allowing you to select a comfortable and safe output.

Consider energy efficiency when setting temperatures. Lowering the thermostat by just one degree can significantly reduce energy consumption. Regularly review and adjust settings based on seasonal changes and personal preferences. Always refer to the manual for specific temperature ranges and recommended settings for optimal performance and safety.

Adjusting Hot Water Settings

The Vokera Easi Heat Plus allows precise control over your domestic hot water supply. Access the hot water settings through the boiler’s control panel, typically indicated by a tap or shower icon. You can adjust the desired water temperature, ensuring comfortable showers and efficient appliance operation.

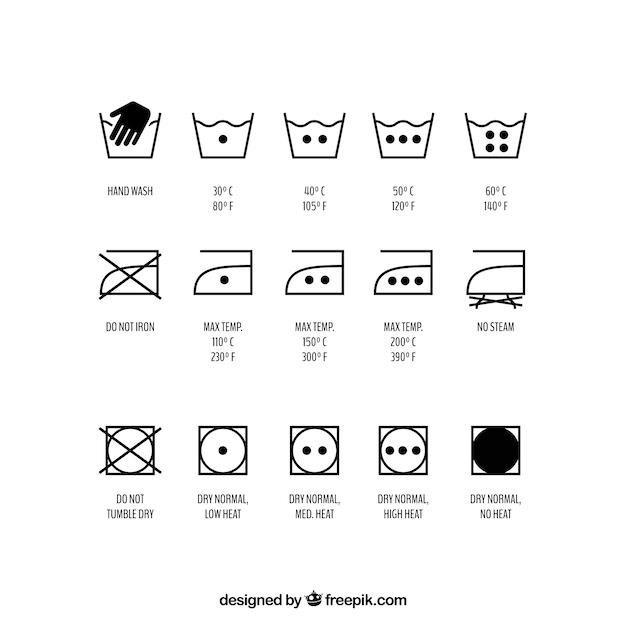

Many models offer pre-set temperature options, or allow for manual adjustment within a specified range. Be mindful of Legionella prevention; maintaining a minimum hot water temperature of 60°C (140°F) periodically is crucial to eliminate harmful bacteria.

Consider your household’s needs and energy conservation. Lowering the hot water temperature slightly can reduce energy consumption, but ensure it remains sufficient for your daily routines. Regularly check and adjust settings to optimize performance and safety, always consulting the full manual for detailed guidance and specific model features.

Troubleshooting Common Issues

Encountering problems with your Vokera Easi Heat Plus? This section addresses frequent issues. First, check the system pressure – low pressure often indicates a water leak or requires refilling (refer to the ‘Filling the System’ section). If the boiler isn’t igniting, ensure the gas supply is on and the unit isn’t locked out due to repeated failed attempts.

Error codes displayed on the control panel are vital clues. Consult the ‘Error Codes and Their Meanings’ section for specific interpretations and recommended actions. Simple resets, often achieved by turning the boiler off and on, can resolve minor glitches.

However, never attempt complex repairs yourself. For persistent issues, or if you suspect a gas leak, immediately contact a qualified heating engineer. Prioritize safety and consult the full manual before attempting any troubleshooting steps, ensuring you understand the potential risks involved.

Boiler Not Igniting

If your Vokera Easi Heat Plus fails to ignite, several factors could be at play. First, verify the gas supply is active – check other gas appliances to confirm. A tripped gas valve or empty gas tank are common culprits. Next, inspect the boiler’s control panel for any error codes; these provide valuable diagnostic information (see ‘Error Codes and Their Meanings’ section).

Repeated ignition failures can trigger a lockout. Try resetting the boiler by switching it off for a few minutes, then back on. Ensure the condensate pipe isn’t frozen, especially during colder months, as this can prevent proper operation. A faulty ignition electrode or flame detection sensor may also be the cause.

Crucially, do not attempt to disassemble or repair the gas components yourself. If the problem persists, contact a qualified Gas Safe registered engineer immediately. Ignoring a gas-related issue can be dangerous.

Low Water Pressure Problems

Insufficient water pressure is a frequent issue with the Vokera Easi Heat Plus. Check the boiler’s pressure gauge; it should ideally be between 1 and 1.5 bar. Low pressure prevents efficient heating and hot water production. A common cause is a water leak somewhere in the system – inspect radiators, pipes, and the boiler itself for any signs of dampness.

Air trapped within the system can also mimic low pressure. Bleed your radiators starting with the ones furthest from the boiler to release trapped air. If pressure remains low after bleeding, you’ll need to re-pressurize the system. Locate the filling loop (usually near the boiler) and carefully follow the instructions to add water until the desired pressure is reached.

Repeatedly low pressure indicates a leak that needs professional attention. Contact a qualified heating engineer to diagnose and repair the leak. Do not over-pressurize the system, as this can cause damage.

Error Codes and Their Meanings

The Vokera Easi Heat Plus utilizes error codes to diagnose potential issues. These codes are displayed on the control panel, providing valuable clues for troubleshooting. A flashing light accompanied by a numerical code indicates a specific problem requiring attention.

For example, code ‘101’ often signifies a flame detection error, meaning the boiler isn’t detecting a stable flame during ignition. Code ‘203’ typically points to a low water pressure issue, requiring system repressurization. Code ‘305’ may indicate a problem with the pump or circulation.

Consult the full error code list in this manual’s appendix for a comprehensive explanation of each code. Some errors can be resolved with simple steps like resetting the boiler, while others necessitate professional assistance. Never attempt repairs yourself if you are not a qualified heating engineer. Always record the error code before contacting support.

Safety Precautions

Prioritizing safety is paramount when operating the Vokera Easi Heat Plus boiler. Always ensure adequate ventilation in the boiler room to prevent the build-up of harmful fumes. Never block or obstruct the flue, as this can lead to carbon monoxide poisoning – a potentially fatal hazard.

Regularly inspect the boiler for any signs of damage or leaks. Do not attempt to repair the boiler yourself unless you are a qualified and certified heating engineer. Keep flammable materials well away from the appliance. Children and vulnerable individuals should be supervised around the boiler.

In the event of a gas leak, immediately turn off the gas supply at the meter and contact a qualified gas engineer. Familiarize yourself with the location of the gas shut-off valve. Never ignore unusual smells or noises emanating from the boiler. Always adhere to local safety regulations and building codes.

Carbon Monoxide Awareness

Carbon monoxide (CO) is a colorless, odorless, and highly toxic gas produced by incomplete combustion. A faulty Vokera Easi Heat Plus boiler can potentially release CO, posing a severe health risk to occupants. Installing a certified CO detector is absolutely crucial, ideally near the boiler and in sleeping areas.

Recognize the symptoms of CO poisoning: headaches, dizziness, nausea, fatigue, and confusion. In severe cases, it can lead to loss of consciousness and even death. If you suspect CO poisoning, immediately evacuate the premises and call emergency services.

Ensure your boiler is serviced annually by a qualified Gas Safe registered engineer to identify and rectify any potential issues that could lead to CO production. Never ignore any warning signs, such as a yellow flame instead of blue, or soot around the boiler. Regular maintenance is your best defense against this silent killer.

Regular Maintenance Procedures

Maintaining your Vokera Easi Heat Plus boiler is vital for efficiency and longevity. Annual servicing by a Gas Safe registered engineer is non-negotiable, ensuring all components function safely and optimally. This includes a thorough inspection of the flue, burner, and heat exchanger.

Beyond professional servicing, several tasks can be performed by the homeowner. Regularly check the system pressure, maintaining it within the manufacturer’s recommended range (typically between 1 and 1.5 bar). Visually inspect the boiler for any leaks or corrosion.

Descaling the boiler annually prevents limescale buildup, improving heat transfer and reducing energy consumption. Filter cleaning, as outlined in the manual, removes debris and ensures proper water flow. Keep the area around the boiler clear of obstructions to allow for adequate ventilation and easy access for servicing. Consistent upkeep minimizes breakdowns and maximizes performance.

Descaling the Boiler

Limescale buildup within the Vokera Easi Heat Plus boiler significantly reduces heating efficiency and can lead to component failure. Descaling removes these mineral deposits, restoring optimal performance. The frequency depends on water hardness in your area; hard water requires more frequent descaling – typically annually.

The process involves using a commercially available descaler specifically designed for boilers. Always follow the descaler manufacturer’s instructions carefully, as incorrect usage can damage the system. Typically, the descaler is mixed with water and circulated through the boiler for a specified period;

Before starting, isolate the boiler from the mains power supply. After descaling, thoroughly flush the system with clean water to remove any remaining descaling solution. Regular descaling extends the boiler’s lifespan and maintains its efficiency, saving energy and reducing repair costs. Consult your manual for specific descaling procedures for your model.

Checking the System Pressure

Maintaining correct system pressure is crucial for the efficient and safe operation of your Vokera Easi Heat Plus boiler. The ideal pressure typically falls between 1 and 1.5 bar (check your specific model’s manual for exact requirements). Low pressure can prevent the boiler from firing, while excessive pressure poses a safety risk.

The system pressure is displayed on the boiler’s control panel. Regularly – ideally weekly – check this reading. If the pressure is too low, you’ll need to repressurise the system. This usually involves opening the filling loop valve to allow water from the mains to enter the system until the desired pressure is reached.

Always close the filling loop valve once the correct pressure is achieved. If you frequently need to repressurise the system, it may indicate a leak somewhere in the heating circuit. Contact a qualified heating engineer to investigate and repair any leaks promptly. Consistent monitoring ensures optimal performance and prevents potential issues.

Filter Cleaning and Replacement

Regular filter maintenance is vital for the longevity and efficiency of your Vokera Easi Heat Plus boiler. The filter prevents debris and sludge from circulating within the system, protecting key components from damage and ensuring optimal heat transfer. A blocked filter can lead to reduced performance and potential breakdowns.

The location of the filter varies depending on the model, but it’s typically found on the return pipe near the boiler. Consult your boiler’s specific manual for precise instructions on accessing and removing the filter. Cleaning involves flushing the filter under cold water to remove any accumulated debris.

Filters should be cleaned annually, or more frequently if you have hard water or a system prone to sludge build-up. Over time, filters may become damaged or corroded and require replacement. A qualified heating engineer should perform filter replacement to ensure proper installation and system integrity. Ignoring filter maintenance can void your warranty.

Advanced Settings and Customization

The Vokera Easi Heat Plus offers a range of advanced settings to tailor performance to your specific needs. Accessing these options typically involves navigating the control panel and entering a service mode, requiring a degree of technical understanding. Incorrect adjustments can impact boiler efficiency and safety, so proceed with caution.

Customization options may include adjusting the heating curve, which dictates how the boiler responds to temperature changes, and modifying the hot water priority settings. Time and date configuration is crucial for accurate programming of schedules and timers. The ‘Holiday Mode’ function allows for reduced energy consumption during extended absences.

If your model supports remote control or app connectivity, you can manage these advanced settings remotely, offering greater convenience and control. Always refer to the full manual for detailed explanations of each setting and potential consequences of adjustments. Consider consulting a qualified engineer for assistance if you are unsure.

Time and Date Configuration

Accurate time and date settings are fundamental for utilizing the Vokera Easi Heat Plus’s programming features effectively. These settings enable precise scheduling of heating and hot water, maximizing comfort and energy efficiency. Typically, configuration is accessed through the boiler’s control panel, navigating to a ‘Settings’ or ‘System’ menu.

The process usually involves selecting the current date, month, and year, followed by setting the correct time, including hours and minutes. Some models may automatically synchronize with a network if connected, simplifying this process. Ensure daylight saving time is correctly enabled or disabled according to your location and the current time of year;

Incorrect time and date settings can disrupt programmed schedules, leading to unexpected heating or hot water operation. Refer to the detailed instructions in your Vokera Easi Heat Plus manual for specific guidance on navigating the control panel and configuring these essential settings. Double-check your entries to avoid errors.

Holiday Mode Functionality

The Vokera Easi Heat Plus incorporates a convenient ‘Holiday Mode’ designed to maintain frost protection while minimizing energy consumption during extended absences. This feature allows you to set a return date, and the boiler will automatically reduce heating output, preventing frozen pipes without fully heating the property.

Activating Holiday Mode typically involves accessing the ‘Settings’ or ‘Program’ menu on the control panel. You’ll then be prompted to enter the duration of your absence, usually in days. The boiler will maintain a minimum temperature, typically around 5°C (41°F), to safeguard the system from freezing damage.

Upon your return, simply deactivate Holiday Mode, and the boiler will resume its normal programmed schedule. Consult your Vokera Easi Heat Plus manual for precise instructions on activating and deactivating this feature, as the process may vary slightly depending on the specific model. Utilizing Holiday Mode offers significant energy savings and peace of mind.

Remote Control Operation (if applicable)

Certain Vokera Easi Heat Plus models offer compatibility with remote control systems, providing enhanced convenience and control over your home heating. These systems typically utilize a dedicated remote control handset or, increasingly, smartphone applications via a connected hub.

Remote control functionality allows you to adjust room temperatures, set heating schedules, and even activate or deactivate the boiler from a distance. This is particularly useful for ensuring a warm welcome upon your return home or for managing heating costs while away.

To establish remote control operation, you may need to pair the remote control or app with the boiler’s control unit, following the instructions provided in your Vokera Easi Heat Plus manual. Ensure the hub (if required) is properly connected to your home’s Wi-Fi network for app-based control. Explore the app’s features for advanced scheduling and energy monitoring capabilities.

App Connectivity and Features

The Vokera Easi Heat Plus, when paired with a compatible hub, unlocks a world of control through its dedicated smartphone application; This app provides a user-friendly interface for managing your heating system remotely, offering convenience and energy-saving opportunities.

Key features typically include remote temperature adjustment, allowing you to pre-heat your home before arrival or adjust settings while away. Advanced scheduling options enable you to create customized heating programs tailored to your lifestyle, optimizing comfort and reducing energy consumption.

The app often displays real-time system status, including boiler temperature and operational mode. Error notifications and diagnostic information can also be accessed, potentially assisting with troubleshooting. Some apps offer energy usage monitoring, providing insights into your heating habits and potential cost savings. Regular app updates ensure compatibility and introduce new features, enhancing your overall experience.

Warranty Information and Support

Your Vokera Easi Heat Plus boiler is covered by a comprehensive warranty, designed to provide peace of mind and protect your investment. Standard warranties typically range from 2 to 10 years, depending on the specific model and registration status. It’s crucial to register your boiler promptly after installation to validate your warranty coverage.

The warranty covers manufacturing defects and component failures under normal operating conditions. Regular servicing, conducted by a Gas Safe registered engineer, is often a requirement to maintain warranty validity. Exclusions may apply for issues arising from improper installation, misuse, or lack of maintenance.

Vokera provides extensive customer support through various channels, including a dedicated helpline, online resources, and a network of accredited service engineers. Their website offers a wealth of information, including FAQs, troubleshooting guides, and downloadable manuals. For urgent assistance, contact the Vokera support team directly to speak with a qualified technician.